Automotive Injection Molding: Shaping the Future of Molded Automotive Parts

Automotive injection moulding has become a cornerstone of the automotive industry, revolutionizing the production of moulded plastic components for vehicles. This advanced manufacturing process has created intricate, lightweight, and durable automotive parts, from interior trim panels to exterior body parts. In this article, we will explore the significance of automotive injection moulding, the role of plastic mold designers, and how this process has transformed the landscape of automotive manufacturing.

The Power of Automotive Injection Molding

Precision and Complexity:

Automotive injection moulding allows for creating highly precise and intricate components with complex geometries. Through computer-aided design (CAD) and computer-aided manufacturing (CAM), plastic parts can be designed and manufactured with exceptional accuracy, meeting the stringent standards of the automotive industry.Lightweight and Cost-Effective:

Injection-molded automotive parts are significantly lighter than their metal counterparts, contributing to fuel efficiency and reducing overall vehicle weight. Additionally, the mass production capabilities of injection moulding make it a cost-effective solution for large-scale manufacturing, enabling automakers to optimize production costs and offer competitive pricing.

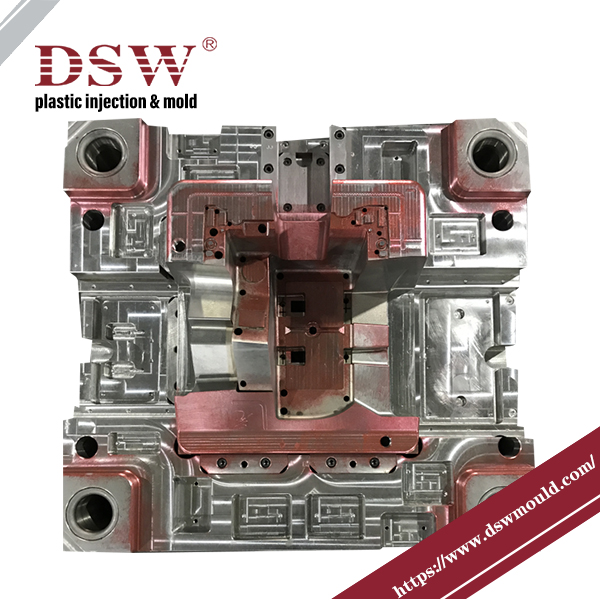

The Role of Plastic Mold Designers

Designing for Manufacturing:

Plastic mold designers play a crucial role in the automotive injection molding process. They collaborate with automotive engineers and designers to create mold designs optimized for manufacturing. This involves considering material selection, part geometry, mold flow analysis, and manufacturing feasibility. By designing molds that are efficient and reliable, plastic mold designers ensure the smooth production of high-quality automotive parts.Iterative Refinement:

Plastic mold designers engage in an iterative refinement process to enhance the mold's performance and functionality. They analyze the mold design, identify potential issues or improvements, and work closely with the manufacturing team to optimize the mold's performance. This iterative approach helps achieve better part quality, reduced cycle times, and increased overall efficiency.

Automotive Injection Molding in Action

Interior Components:

Automotive injection molding is instrumental in producing a wide range of interior components, including dashboard panels, door trims, center consoles, and seating parts. The process allows for integrating various features like textures, patterns, and functional elements such as clips, brackets, and mounting points.Exterior Body Parts:

Injection molding is vital in manufacturing exterior body parts such as bumpers, grilles, fenders, and mirror housings. These parts require high strength, impact resistance, and precise fitment. Automotive injection molding enables the production of these parts with exceptional dimensional accuracy and surface finish.

Conclusion

Automotive injection moulding has transformed the manufacturing of automotive parts, offering unparalleled precision, complexity, and cost-effectiveness. With the expertise of plastic mold designers, the automotive industry continues to push the boundaries of design and engineering, creating innovative, lightweight, and durable components. As the automotive sector embraces advancements in materials, technologies, and design capabilities, the future of automotive injection molding looks promising, paving the way for safer, more efficient, and visually appealing vehicles.

Comments

Post a Comment