Plastic toy molds Manufacfurer

Plastic toy molds are specialized molds used in the manufacturing process of plastic toys. These molds are designed to create the desired shape and structure of the toy through injection molding, a commonly used technique.

|

| plastic toy molds |

The plastic toy mold consists of two halves: the cavity and the core. The cavity is part of the mould that forms the outer surface of the toy, while the core creates the internal structure. These halves are precision-engineered with the desired design, including details, textures, and features specific to the produced toy.

The injection moulding process starts with the molten plastic material being injected into the mold under high pressure. The plastic material fills the cavity and core, taking the shape of the mold. Once the plastic has cooled and solidified, the mold is opened, and the newly formed toy is ejected.

Plastic toy molds are typically made from durable and heat-resistant materials like steel or aluminum. These materials ensure the molds can withstand the high temperatures and pressures involved in the injection molding process, allowing for repeated use and longevity.

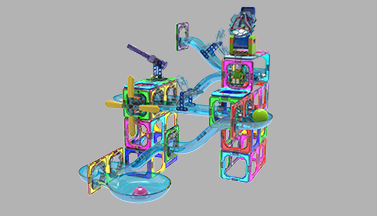

Manufacturers of plastic toys rely on these molds to create various toy designs, ranging from action figures and dolls to vehicles, puzzles, and more. The moulds enable the efficient and cost-effective production of plastic toys on a large scale, ensuring consistent quality and precision in the final products.

Designing and manufacturing plastic toy molds require expertise in mold making, engineering, and understanding the specific requirements of the toy industry. Skilled mold makers and designers work closely with toy manufacturers to create molds that meet the toys' desired specifications, safety standards, and aesthetic appeal.

Plastic toy molds play a crucial role in the toy manufacturing industry, enabling the production of diverse and imaginative toys loved by children worldwide.

Comments

Post a Comment